Honychem provides exclusive customization

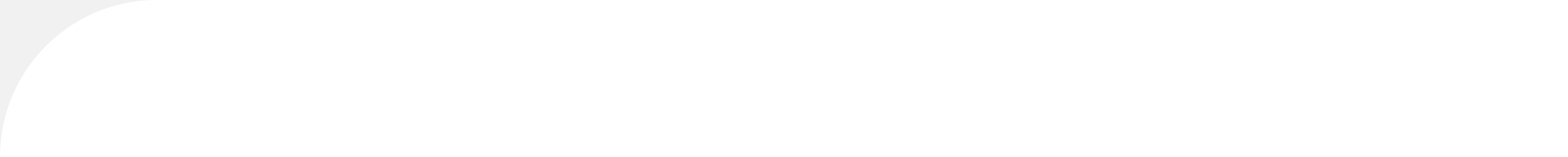

Customized rubber products

Independently developed rubber formula, with molding and injection molding processes, manufacturing pure rubber and rubber products to be skeleton. We have rubber extruders and vulcanization tanks to manufacture rubber pipes, sealing strips, and rubber shaped pipes.

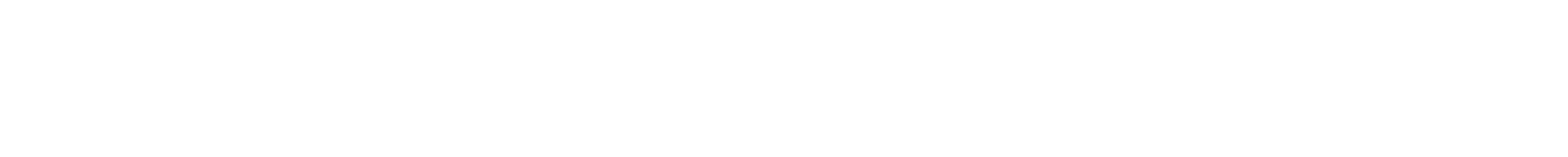

Customized silicone products

We use domestic and foreign brand silicone raw materials specified by the customer, and produce various silicone miscellaneous parts, silicone buttons, silicone tubes, silicone sealing strips, etc. through various molding processes such as molding, injection, and extrusion.

Customized liquid silicone products

There are liquid silicone injection machines from brands such as Engel and Baike, which can produce metal wrapped silicone, plastic wrapped silicone, etc. There are processes and equipment for liquid to solid conversion, mainly producing silicone products in medical, food, and wearable devices.

Customized plastic products

Sumitomo, Haitian and other brands of injection molding machines are mainly used for liquid silicone encapsulation, and also produce medical grade and food grade plastic products.

Mold

processing

We have precision machining equipment such as Makino and Shadik, as well as Zeiss 3D measuring instruments, which can manufacture high-precision non flash molds and cost saving liquid to solid molds.

Our Product

HonyChem always gets the job done

We have professional and experienced technical teams to meet all the needs of customers

Design EngineerMike

Our design engineers are responsible for creating and developing new product designs. They work closely with customers to understand their specific needs and requirements, and then use their expertise in materials science, engineering, and CAD software to create innovative and practical designs.

Material EngineerJason

Our material engineers are experts in the properties and characteristics of different types of rubber and other materials used in our products. They work closely with our design and mold engineers to select the most appropriate materials for each application, taking into account factors such as durability, flexibility, and cost.

Quality Control EngineerKosio

Our quality control engineers are responsible for ensuring that our products meet or exceed customer expectations. They use a variety of testing and inspection techniques to verify that our products meet all relevant standards and specifications, and they work closely with our production team to ensure that all products are manufactured to the highest quality standards.

As a professional company we are hands on business owners and intimately involved in daily operations. Time on the shop floor interacting with employees is routine, promoting their development and be proud of their work.

Our BlogLatest News